Parts Washer Classification

When searching for a parts washer, you probably hear terms like aqueous parts washer, industrial parts washer, manual parts washer, and automatic parts washer. With so many options and choices, what are the differences?

Manufacturers and service industries use automatic parts washers to manage high quantities and clean large parts. Automatic parts washers contain the parts and cleaning fluid during the wash cycle and clean the parts within a fixed time interval.

Manual Parts Washers

For low volume parts cleaning, industries use manual parts washers to remove contaminants from small parts. Manual parts washers typically include a solvent dispensing system and a sink, which is mounted to a drum. An individual must manually clean the parts with a brush and rinse the cleaned parts in the sink with a solvent (low pressure flow).

Automatic Parts Washers

Manufacturers and service industries use automatic parts washers to manage high quantities and clean large parts. Automatic parts washers contain the parts and cleaning fluid during the wash cycle and clean the parts within a fixed time interval. The most common automatic parts washers are:

Cabinet-Style Parts Washers

- Fixed Turntable

- Retracting Turntable

Conveyor Parts Washers

- Belt Conveyor

- Overhead Conveyor

Immersion Parts Washers

- Agitation

- Immersion and Spray

- Ultrasonic

The parts cleaning industry will also refer to automatic parts washers as industrial parts washers because of the unique and customizable designs.

Cabinet-Style Parts Washers

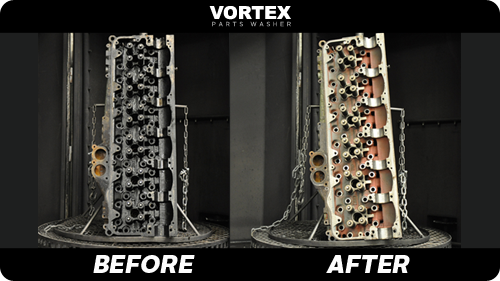

The cabinet-style parts washer uses a high-pressure, heated, aqueous spray to clean parts within a cabinet enclosure. A turntable holds and rotates the parts during the cleaning cycle.

Conveyor Parts Washers

The conveyor parts washers use belts or an overhead conveyor to continuously move parts through the parts washing system. Many of these systems use aqueous chemistries to clean the parts.

Immersion Parts Washers

Immersion or vat-style parts washers clean parts within a bath system. Immersion parts washers use a combination of agitation, spray, or ultrasound and a cleaning fluid to remove part contamination.

Part Cleaning Chemistry

Many of the manual parts washers use organic and petroleum solvents to dissolve and remove contamination from the part.

Most automatic parts washers use heated, aqueous chemistries (water and detergents) to clean the parts. These systems are generally known as aqueous parts washers.

Parts Washer Selection

Choosing the appropriate parts washer depends on the application, part size, part shape, part volume, and level of cleanliness. For more assistance with parts cleaning and parts washers, please contact Vortex.